|

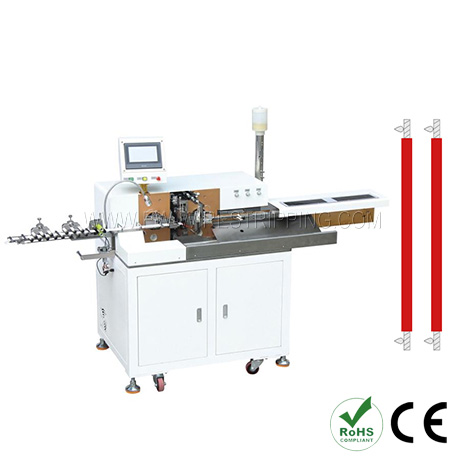

Model

|

EW-8355

|

|

Power

|

2000W

|

|

Power supply

|

AC220/50Hz

|

|

Air pressure

|

0.6Mpa

|

|

Display

|

Touch screen LCD display

|

|

Applicable wire

|

Electronic wire, high temperature wire, Teflon wire, etc.

|

|

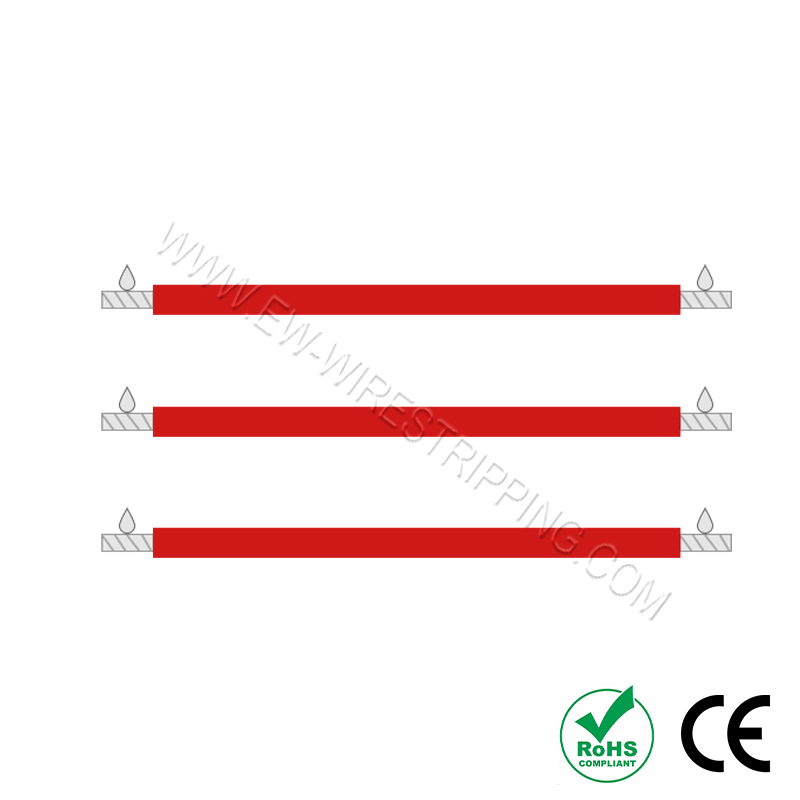

Function

|

Wire cutting, single and double end half stripping and full stripping, single and double end twisting, single end tinning, double end tinning

|

|

Processing range

|

Marking machine 32#~16# wire

|

|

Productivity

|

According to 100mm length, about 1300 times per hour, 6000-18000 pieces/hour, according to n mm length = single dip/double dip, 34m m=1850 times/1535 times; 30mm=1815 times/1480 times; 20mm=1735 times/1395 times; 15mm=1670 times/1320 times; 100mm=1350 times/1150 times; 200mm=1300 times/1100 times; 300mm=1280 times/1090 times; 400mm=1240 times/1060 times; 6 00mm=1160 times/1010 times; 800mm=1100 times/960 times; 32#-28# lines can make 10 lines at the same time; 26#-24# lines can make 8-9 lines at the same time; 22#-20# lines can make 6-7 lines at the same time; 18#-16# lines can make 4-5 lines at the same time; (the length of the line wire is different)

|

|

Wire cutting length

|

10-830 mm (long lines can be customized)

|

|

Stripping length

|

Standard front and rear blade distance 12mm (changeable blade distance: 15mm, 18mm, etc.)

|

|

Tinning length

|

Marking machine range 0.5-11mm (changeable)

|

|

Twisting length

|

Marking machine 2mm-10mm (changeable)

|

|

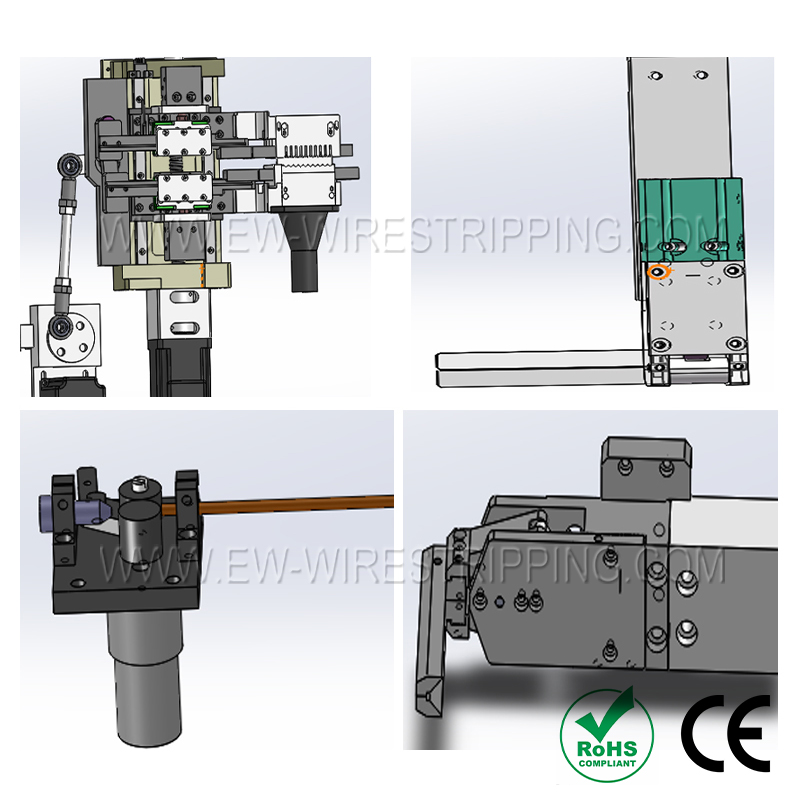

Twisting method

|

Digital motor drive mode

|

|

Detection function

|

Wire shortage detection, wire knotting, air pressure detection

|

|

Transmission structure

|

Precision screw, guide rail, reducer

|

|

Auxiliary device

|

Waste flux collection device/waste tin slag collection device/waste rubber collection device

|

|

Weight

|

380kg

|

|

Appearance size

|

1720*750*1450

|

|

Placement space

|

3 square

|

|

Pedal control

|

N/A

|